Quilt-Control: Powerful and customisable control system for quilting machines

Many manufacturers in the quilting machine industry are facing an upgrade of their control system, which is often already outdated. Outdated performance requirements, increasing quality demands and growing problems with motors and spare parts can be solved with a new control system.

A western Austrian manufacturer of quilting machines decided to switch to a new platform. The machine type - a 3-axis high-performance quilting machine with CNC-like functionality - could be realised cost-effectively thanks to the camming function of a compact controller from B&R Automation.

The result:

Enhanced functionality and a massive improvement in performance data.

The product behind: Quilt-Control

A control system customised for quilting machines, available as an OEM product for quilting machine manufacturers.

Quilt-Control in use at our lead customer: Double the machine performance, modern operation and massive savings.

- Up to 1200 stitches/minute (20 stitches/second)

- Highly dynamic: 250 kg carriage is moved up to 6 mm in 25 ms, true to position

- Patterns defined in the CAD system are read in and processed directly on the control unit

- Easy-to-use visualisation based on HTML5

- Reduction of the control unit price by approx. 40% compared to the previous control unit

Results for the lead customer: Doubling of machine output, cost reduction and much more

Our lead customer, an Austrian quilting machine manufacturer and retrofitter, previously relied on a proprietary control system. Switching to a modern control system based on the X20CP0484 compact controller from B&R brought immediate and significant benefits:

1. reduction of the control unit price by approx. 40% compared to the predecessor control unit

Cost-effective compact control system

Compact control ‘from the catalogue’ offers sufficient performance and is considerably cheaper than the proprietary predecessor system.

Optimised switchgear construction

Instead of a ‘fully equipped control cabinet’ for all machine types, there are cost-effective basic variants with options.

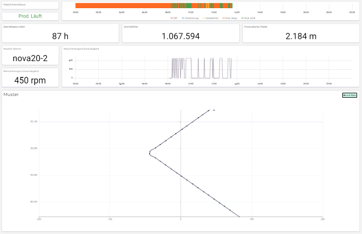

2. double productivity with reference patterns thanks to a revolutionary ‘Jump’ function

With the development of the new control generation, the so-called ‘jump’ (jump movement to a new start position) has also been fundamentally revised. The production of a representative reference pattern, which took 3:10 minutes on the previous machine, now only takes 1:30 minutes. This corresponds to a doubling of productivity, which is transferable to complex designs such as lettering!

3. Improved quality

Due to the high positioning accuracy of the drive control, the stitch accuracy can be significantly improved without changing the mechanics.

Significantly improved stitch quality thanks to high positioning accuracy.

4. Made of latest technology & quilting/embroidery experience

Control system - reduced to the max!

The requirement to implement a CNC-like application cost-effectively resulted in the decision in favour of an X20CP0484 compact control system from B&R Industrial Automation, with which this requirement could be implemented without dedicated CNC functionality.

The resulting machine performance is impressive:

- Up to 1200 stitches/minute (20 stitches/second)

- High dynamics: 250 kg carriage is moved up to 6 mm true to position in 25 ms

Operation: future-proof with HTML5

Panel: Powerpanel T50 von B&R

New, easy-to-use visualisation based on HTML5

Patterns defined in the CAD system are read directly into the control system and processed there

5. Integration of your individual requirements

The transparent software design and the open architecture of the B&R hardware enable seamless and uncomplicated integration of your specific requirements.

"With over 25 years of experience in the embroidery and quilting industry - including many years as a control partner of Saurer Embroidery - we know the key success factors for a high-performance control system. Based on Quilt-Control, we take your electrical engineering and control software to a whole new level.“

Markus Hanefeld, Business Development

6. Long-Term Spare Parts Availability

Quilt-Control is based on the latest control components from B&R, an ABB Group company. This ensures the long-term availability of spare parts.

Quilt-Control integration examples

Duplomat

Novastep

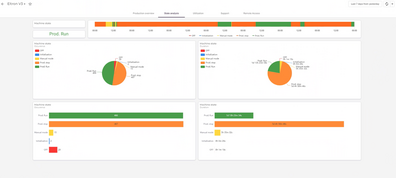

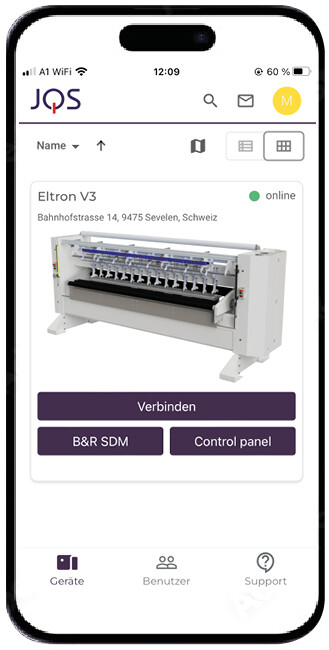

7. IoT-Ready

Thanks to the integration of IXON Cloud, Quilt-Control already offers reliable and powerful remote maintenance access. The solution also enables the storage of historical data, creating the basis for IoT applications.

Thanks to the IXON Cloud Mobile app, access can be conveniently gained via mobile devices such as smartphones or tablets.

Visualisation of the current pattern

Available as a mobile app for mobile phones and tablets

Would you like to find out more about Quilt-Control?

Would you like to raise your quilting machines to a new level with a state-of-the-art control system? We look forward to answering your questions.

We can also organise an online demo of Quilt-Control.

Send us an e-mail and we will get back to you!